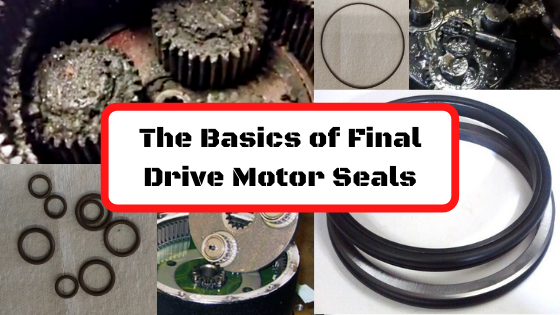

The Basics of Final Drive Motor Seals

Jun 9th 2020

If you’ve ever opened up a hydraulic motor, you’ve noticed that there are a number of seals, o-rings, and gaskets. The goal of this Shop Talk Blog post is to familiarize you with the purpose of those seals, help you recognize them, and provide some hints for installing new seals.

Here are a few other Shop Talk Blog posts you might find helpful:

Drive Motor Seals

The Importance of Seals in a Final Drive Motor

Seals, as the name implies, are intended to seal fluids within something. In some instances, they may also be responsible for keeping two different fluids separate from each other (like hydraulic fluid and gear oil). Seals keep critical fluids where they need to be, and keep those fluids protected from contaminants like water, dirt, sand, grit, etc.

Types of Seals

The major seals found in a final drive motor are the face seals, common lip seal, quad o-ring seals, and brake seals.

Face Seal

Face seals have a lot of different names: floating face seals, main seals, duo-cone seals, and floating seals. The face seal is a mechanical seal located where the hub and the axle come together. These seals consist of two precision ground metal rings and two large rubber o-rings. Of all the seals you’ll find in your drive motor, this one is the most important and is exposed to the most work-site contamination.

Common Lip Seal

You’ll find common lip seals on the axle where the separate the hydraulic fluid in the main housing from the axle hub.

Quad O-Ring Seals

If you’ve got a radial piston final drive, you’ll find quad o-ring seals. They are used on the main housing and the hub to seal the cam ring and are about 8” in diameter. You can also find them the seal the brake housing to the main housing, but these quad o-ring seals are smaller (about 4” in diameter).

Brake Seal

You may also find a brake seal on the brake piston. It’s usually about 3” in diameter and is typically a simple o-ring or a lip seal in a metal housing.

Why a Leaky Seal is Serious

When you’ve got a seal that’s leaking, your first instinct may be to wait until it gets a little worse before devoting the time and money to getting that seal replaced. But here’s the problem: a bad seal doesn’t just let fluid leak out, but it let’s contaminants work their way in.

Contaminants can include abrasive particles like dirt, sand, grit, and dust, as well as moisture and air. Abrasive particles will accelerate how fast your final drive wears out and reduce its efficiency in the process. In newer machines, they can do even more damage and easily get trapped in the clearances between components.

Moisture contamination also affects final drive performance,and it can also make existing cavitation issues worse while causing corrosion issues to develop.

To make matters worse, as the seal degrades further, it can get inside your final drive, too. Seal particles, along with abrasive contamination, can also clog up your filters and reduce their useful life. In short, don’t ignore those leaking seals.

Drive Motor Seal Installation Tips

Here are some tips to help you get the seals installed on your final drive motor:

- Never reuse seals -- always install brand new seals when you’ve opened up your drive motor.

- Don’t try to use seals that are cut, cracked, or damaged

- When you buy a cheap, off-brand seal, you’ll get what you pay for

- Follow manufacturer’s instructions for installing seals

- Be careful about substituting seals and o-rings with a different kind -- it really isn’t a good idea unless you know quite a bit about seal (seal materials are chosen for things like their compatibility with fluids, operating temperature, pressure, and shaft speed)

- Use light lubrication when installing seal

- Most seals can be installed by hand with a pusher tool of some sort, although some seals require special tools and an arbor press

- Finally, check online for practical videos that show seals being installed

Conclusion

The seals on your drive motors keep fluids where they belong and keep contamination out. That’s why it's important to replace your seals when they begin to leak, show signs of damage, or when you’re reassembling a drive motor.

![Final Drive Cores and the Remanufacturing Revolution [VIDEO]](https://cdn11.bigcommerce.com/s-lbnln0ppxx/images/stencil/original/uploaded_images/final-drive-cores-and-the-remanufacturing-revolution.png?t=1705357426)