Gear Oil Issues – Troubleshooting a Final Drive

Dec 21st 2017

Final Drive Gear Oil Recommendations

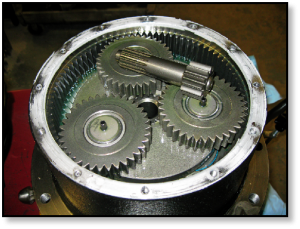

In this post, we are going to look at troubleshooting gear oil problems in your final drive. We typically recommend checking the gear oil about once every 100 hours of operation and changing the oil at least once a year. Let’s take a look at what kind of issues can arrive in connection with gear oil.

Gear Oil Leak

The first gear oil issue we’re going to look at is the simplest: an oil leak. While it’s easiest just to keep topping off the oil level, an excessive loss of oil is something that shouldn’t be ignored.

How can you tell if the leak is gear oil or hydraulic fluid? Well, hydraulic fluid is going to have a much thinner consistency than gear oil, so if the leak is a thin fluid then it is likely hydraulic fluid. A final drive only contains about two quarts of gear oil on average, so if there is an excessive amount of fluid leaking then, again, it is going to most likely by hydraulic fluid.

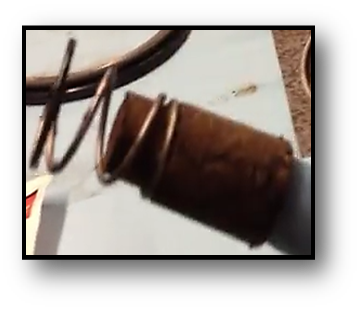

If oil is leaking from behind the sprocket, and possibly on the tracks themselves, then the most likely culprit is a leaking lifetime seal, also known as a floating face seal, main seal, mechanical face seal, or duo-cone seal. If this is the case, then you need to replace the floating face seal as soon as possible.

If the oil is coming from the gearbox cover, then it could be that the cover or casing has been physically damaged. In that case, you would need to replace the cover o-ring. If that doesn’t solve the problem, then the cover itself may need to be replaced or the gear hub casing may need to be machined to remove the distortion.

However, there could be another cause for a leak from behind the sprocket as well as a leak from the gearbox cover, and it is much more serious. The leak could be caused by a pressure build-up in the gear box, which requires a professional evaluation to determine the source of the problem.

Gear Oil Level Too High

The opposite of a leak is having the gear oil level too high. This can happen when hydraulic oil leaks into the gearbox. One potential cause is a worn oil seal or bearings. If this is the case, they would need to be replaced as soon as possible.

If the case drain filter isn’t checked often enough, pressure can build up in the case drain line. As this pressure builds up, it will blow the oil seal and allow that hydraulic fluid–which is under high pressure–to enter the gearbox. This is a serious problem, and if not addressed it can devastate your final drive.

And by “devastate” we mean things like crack the cover or blow it off at high speed. That’s why checking and replacing the case drain filter according to manufacturer specifications is something that should never be ignored.

Conclusion

Gear oil issues should never be ignored, whether its low gear oil levels pointing to a leak or high gear oil levels that indicate a clogged case drain filter. That's one of the reasons why its important to keep track of the gear oil levels in your final drive hydraulic motor.

![Final Drive Cores and the Remanufacturing Revolution [VIDEO]](https://cdn11.bigcommerce.com/s-lbnln0ppxx/images/stencil/original/uploaded_images/final-drive-cores-and-the-remanufacturing-revolution.png?t=1705357426)