Understanding the Importance of Hydraulic Line Maintenance

Posted by Dr. Sara McCaslin on Feb 2nd 2024

There's nothing like being on a time-critical job and realizing that one of your critical hydraulic lines has failed. Discover the common signs of hydraulic line failure and learn how to prevent costly damage. Don't let a failing hydraulic line bring your operations -- including your final drive motor -- to a halt!

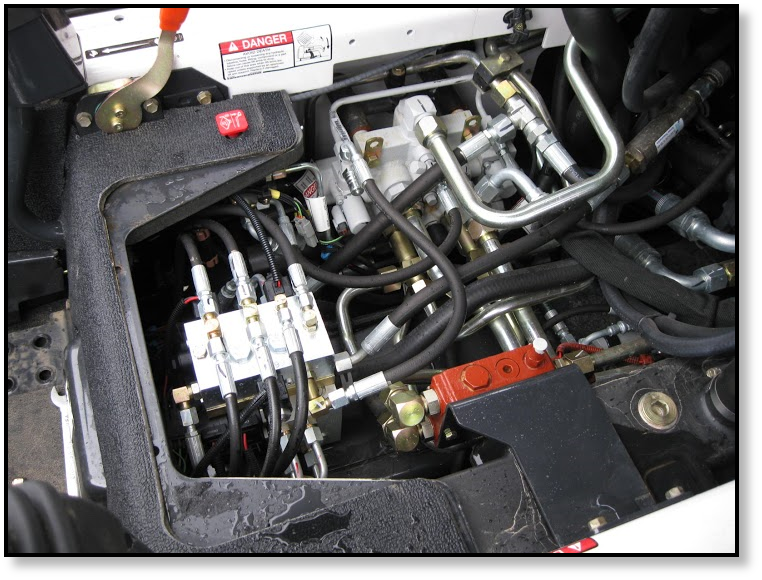

Proper maintenance of hydraulic lines is crucial to ensure the smooth operation and longevity of your compact equipment. Regular inspection and upkeep can help identify potential issues before they escalate into costly failures. By understanding the importance of hydraulic line maintenance, you can prevent downtime and avoid expensive repairs.

Hydraulic lines transmit fluid pressure and power throughout your machinery. Any failure in these lines can result in decreased efficiency, compromised safety, and even catastrophic equipment damage.

Regularly inspecting hydraulic lines for signs of wear, leaks, or damage can help you catch potential issues early on. Look out for any cracks, abrasions, bulges, or kinks in the lines. Additionally, pay attention to any unusual noises, vibrations, or performance issues that may indicate a problem with the hydraulic system. By proactively addressing these maintenance needs, you can prevent hydraulic line failure and ensure the reliability of your equipment.

Identifying the 5 Warning Signs of Hydraulic Line Failure

Identifying the warning signs of hydraulic line failure is crucial for preventing costly damage and minimizing downtime. Here are some common signs to look out for:

1. Leaks: Hydraulic fluid leaks clearly indicate a problem with the hydraulic lines. Check for any puddles or drips of fluid beneath your equipment.

2. Decreased Performance: If you notice a decrease in the efficiency or power of your machinery, it could be a sign of hydraulic line failure. Keep an eye out for sluggish operation or difficulty in lifting or moving heavy loads.

3. Unusual Noises or Vibrations: Any unusual noises, such as whining, grinding, or excessive vibrations, can indicate a problem with the hydraulic system. These issues should be addressed promptly to prevent further damage.

4. Increased Temperature: If the hydraulic lines feel hot to the touch or you notice a rise in temperature in the system, it could be a sign of excessive friction or a restriction in the flow of hydraulic fluid.

5. Visual Inspection: Regularly inspect the hydraulic lines for any visible signs of wear, such as cracks, abrasions, bulges, or kinks. These can weaken the lines and lead to failure over time.

If you notice any of these warning signs, it is essential to take immediate action. Ignoring hydraulic line issues can result in severe damage to your equipment, costly repairs, and potential safety hazards.

The Dangers of Ignoring Hydraulic Line Issues

Ignoring hydraulic line issues can have severe consequences for your equipment and operations. Here are some dangers of neglecting hydraulic line maintenance. For example, hydraulic line failure can cause significant damage to your machinery, resulting in costly repairs or even the need for replacement. The force exerted by hydraulic systems can be immense, and a failure can lead to broken components, leaks, or even complete system failure.

And when hydraulic lines fail, your equipment will be out of commission until the issue is resolved. This downtime can disrupt operations, delay projects, and result in financial losses. Then there are safety hazards: a failing hydraulic line can pose serious safety risks to operators and those working nearby. Sudden bursts, leaks, or pressure releases can cause injuries, fluid contamination, or fires. Ensuring the integrity of hydraulic lines is crucial for maintaining a safe working environment.

By ignoring hydraulic line issues, you are gambling with your equipment's reliability, performance, and safety. It is always better to address maintenance needs promptly and prevent potential failures.

Preventing Hydraulic Line Failure: Tips and Best Practices

Preventing hydraulic line failure requires a proactive approach to maintenance and regular inspections. Here are some tips and best practices to help you keep your hydraulic lines in optimal condition:

1. Perform Regular Inspections: Schedule routine inspections of your hydraulic lines to check for any signs of wear, leaks, or damage. Look for cracks, abrasions, bulges, or kinks that may weaken the lines.

2. Take the Time for Proper Installation: Ensure that hydraulic lines are installed correctly, following the manufacturer's guidelines and recommendations. Incorrect installation can lead to premature failure or performance issues.

3. Use Quality Components: Invest in high-quality hydraulic lines, fittings, and seals to ensure durability and reliability. Inferior components can wear out quickly, leading to failures and leaks.

4. Monitor Fluid Levels and Quality: Regularly check hydraulic fluid levels and monitor its quality. Contaminated or degraded fluid can damage hydraulic lines and other components. Follow the manufacturer's recommendations for fluid change intervals.

5. Train Operators: Train equipment operators on the importance of hydraulic line maintenance and the warning signs of failure. Encourage them to report any abnormalities or concerns immediately.

By following these preventive measures and establishing a comprehensive maintenance program, you can minimize the risk of hydraulic line failure and prolong the lifespan of your equipment.

Conclusion

Hydraulic line failure can have detrimental effects on your equipment, productivity, and safety. By understanding the signs of hydraulic line failure and implementing preventive measures, you can avoid costly damage and ensure the reliable operation of your machinery. Regular maintenance, inspections, and prompt repairs are essential for keeping hydraulic lines in optimal condition. Don't underestimate the importance of proactive hydraulic line maintenance. It can save you from unexpected downtime, expensive repairs, and potential accidents. And don't forget to be safe!

Remember, if you notice any warning signs of hydraulic line failure, it is crucial to take immediate action. Addressing issues promptly can prevent further damage and keep your operations running smoothly. Don't let a failing hydraulic line bring your productivity to a halt!