Hydraulic Drive Motor Contamination: What You Need to Know

Mar 9th 2019

Hydraulic Drive Contamination

| Hydraulic contamination can be a major source of problems for hydraulic systems, including hydraulic motors and final drives. In this Shop Talk Blog post, we are going to talk about the types and sources of contamination, as well as how to avoid contamination in your hydraulic systems. This information is important for all types of hydraulic construction equipment, from a Terex CTL to a Bobcat skid steer. Whether you have a final drive motor or a track drive motor, contamination can be a problem. |

Types of Contamination

|

Some forms of

hydraulic contaminationcan be seen with the naked eye and are usually in the form of particles. Slivers of metal or flakes or rust can be easy to spot in hydraulic fluid, and can usually be removed from the system by filters. However, the filters need to be changed regularly, and such contaminants can still do a great deal of damage before they are stopped by a filter.

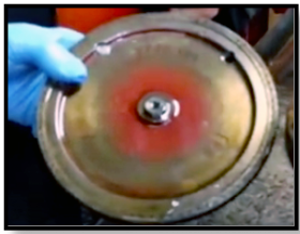

This image shows brass particles on the inside of a final drive motor cover plate. This kind of contamination can seriously damage the components inside your final drive, such as the bearing and gears. It can wreak havoc with the rotary group, too. Another type of contamination that can sometimes be spotted with the naked eye is the presence of water or air in the hydraulic fluid. Water can cause the fluid to appear milky, and air tends to make the hydraulic fluid look frothy. Both of these can cause severe damage to the hydraulic system and your final drive. Effects of water and air contamination include cavitation and erosion. |

There are other forms of contamination that can’t necessarily be seen with the naked eye, however. They result from the natural breakdown of the hydraulic fluid and its additives over time (which is one of the reasons why it should be changed out regularly), or can result from chemical reactions between the fluid and water in the hydraulic system. The best way to deal with the effects of chemical breakdown and reactions is to drain the hydraulic fluid and replace with fresh, filtered fluid.

Preventing Contamination

To prevent most forms of contamination, follow these simple guidelines:

- Filter all hydraulic fluid before it is added to the system

- Drain and replace the hydraulic fluid as recommended by the manufacturer

- Maintenance and repairs should be performed in a clean environment

- Change all filters and breathers per manufacturer recommendations

- Check seals for leaks — if something can leak out, contaminants can make their way in — and replace them as needed.

When it comes to preventing damage to your final drive from hydraulic contamination, the key is to check and change the case drain filter. Most hydraulic motors have a case drain line and filter. If that filter becomes clogged, excessive pressure builds up in the hydraulic motor and can result in catastrophic damage. Again, this can be avoided by checking and changing the case drain filter on a regular basis.

Contamination can be introduced when hydraulic equipment is being serviced, especially if it is serviced in the field where dirt and debris abounds. The exterior should always be cleaned before it is serviced (you’ll notice that we thoroughly clean the exteriorof hydraulic motors before beginning the disassembly step).

Be especially careful when removing the hoses from your final drive or hydraulic motor. Be sure to plug hoses and ports immediately. Also note that different types of hydraulic fluid should never be mixed. Reactions can occur between the additives that can result in damage to your system.

Hydraulic fluid should be stored in sealed containers away from fluctuating temperatures. Any time a container is opened, it should not remain open any longer than necessary. Not only could particle contaminants make their way in, but the fluid might also absorb moisture or air.

Conclusion

All hydraulic systems are susceptible to damage from contamination, but especially hydraulic motors and final drives. Radial piston hydraulic motors, for example, can suffer irreparable damage to the cam ring if abrasive particles are not filtered out of the system. The key to keeping your hydraulic equipment free of contaminant damage is to filter the hydraulic fluid before it goes into the system, drain and replace the hydraulic fluid regularly, check and change the filters and breathers, and only open up the hydraulic system in a clean environment.

FinalDriveParts.com provides new and reman final drive motor for most OEM brand heavy equipment, excavators and mini-excavators. Check out the latest in inventory in out Final Drive Shop.