Final Drives: Gearing Up

Jan 3rd 2018

Final Drives and Gears

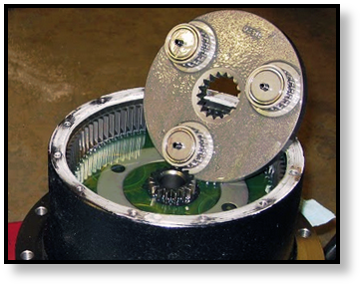

The purpose of gears in a final drive is to provide speed reduction and generate torque. Gears are one of the critical components of your final drive, and they carry some its the heaviest loads and most intense forces.

Final Drive Gears and Surface Hardening

The gear teeth are where the actual loads get transferred as they push against each other. This requires a very hard surface that resists damage. If the entire gear were hardened all the way through, it would become too brittle to serve its purpose. That’s why a surface hardening process is used to just harden the surface of the gear while leaving the inside still ductile enough to be tough and not brittle. The surface treatment typically used on the type of gears found in final drives is called carburizing and is sometimes referred to as a case hardening process.

As a result of the carburizing process, the gears can carry the loads involved in with reducing speed and generating torque for thousands of hours without sustaining any significant damage.

Final Drive Gears and Gear Oil

Gear oil (also referred to as gear lube) is a vital part of the life and performance of these gears. The gear oil provides a surface film between the gear teeth, preventing the metal-to-metal contact that can do devastating damage at high speeds, forces, and torques. That is why it is so important to check and change the gear oil on a regular basis. Additionally, gear oil provides corrosion protection.

Damage to Gears in a Final Drive

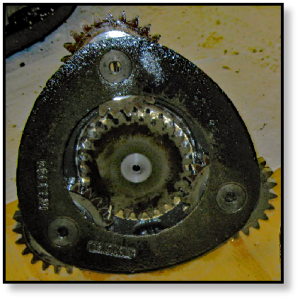

Some of the damage to gears is related to the gear lube. When it becomes contaminated with debris, for example, the gears experience cracking and pitting on the surface, which in turn leads to more catastrophic-type damage. When the gear oil isn’t changed often enough, it leads to faster surface wear and a significantly shorter lifespan for the gears. This faster surface wear can actually cause the gear teeth to wear away until they can’t do their job anymore.

The image below shows the lower shaft from a Hy-Dash final drive where the gear teeth were significantly worn down. The final drive failed because the gear teeth were so worn down they could no longer engage with the coupler. This meant that no matter how fast the lower shaft would turn, the upper shaft never turned because no torque could be transferred.

When the machine itself is abused (i.e., running at high speeds for extended periods of times, unnecessary overloading, etc.), the gear teeth can start to bend and eventually fracture. Broken gear teeth will quickly lead to severe damage in other parts of the final drive but, fortunately, they do not occur very often. Gears need to be replaced when the teeth no longer have a flat surface on the edge of the splines, which makes the tips almost look like jagged points. If your gears look like this, they need to replaced as soon as possible.

Conclusion: Gears Integral Part of Final Drive

Gears are an integral part of your final drive, which explains why we place so much emphasis on regular maintenance involving gear lube. If you take good care of your gears, they’ll take good care of you — which includes replacing them when they are worn out.

![Final Drive Cores and the Remanufacturing Revolution [VIDEO]](https://cdn11.bigcommerce.com/s-lbnln0ppxx/images/stencil/original/uploaded_images/final-drive-cores-and-the-remanufacturing-revolution.png?t=1705357426)