Blast from the Past: The First Hydraulic Motor

Sep 17th 2018

First Hydraulic Motor from 1876 Still Running

Do you know the year that the first hydraulic drive was installed for use? Try 1876. And it still runs!

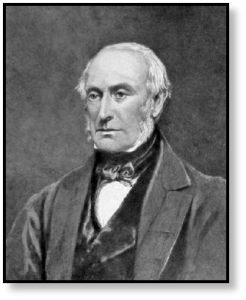

Lord William Armstrong

Lord William George Armstrong was a talented Englishman who had given up a most promising career in law to follow his true dream of being an engineer, and it seems he certainly made a wise choice. He established the engineering firm W.G. Armstrong and Company, and one of its most monumental contributions (among many others) was the Swing Bridge over the River Tyne (also known as the Newcastle Swing Bridge).

So, what does this have to do with hydraulic motors? Well, the hydraulic motors he designed to power the bridge are still in use.

Swing Bridge over the River Tyne

The swing bridge connected Newcastle on Tyne to Gateshead. Bridges in one form another had stood in that spot since the Romans. However, by the late 1800s a need developed for a swing bridge that would allow large ships to pass for the purposes of commerce and industry. Armstrong’s firm had a vested interest in the bridge, and were responsible for its design and function.

The bridge itself is 281 feet long. It was designed as a cantilevered span, and rotates 360° about it’s central axis. The entire bridge weighs 1,500 tons, and the rotating span weights 900 tons.

Bridge Rotation

The bridge span, weighing 900 tons, rotates about a central pivot. That central pivot was designed somewhat similar to a gun turret as it is supposed by a ring of massive rollers. These rollers are 360 inches in diameter and turn on a 50 foot diameter roller path. The bulk of the weight of the span is floating on a 62″ diameter water press with 700 psi of pressure.

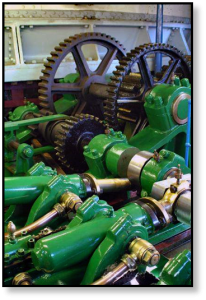

Hydraulic Power Transmission

One of the key aspects of the design was the mechanism to actually rotate the bridge span to allow ships to pass through. Armstrong opted for transferring power via what was readily available beneath the bridge: water. Armstrong developed a three-cylinder oscillating hydraulic motor that worked with a set of steam powered hydraulic pumps that used about one ton of per week during its heyday. Note that the steam powered pumps were not replaced by electric pumps until 1959.

A hydraulic accumulator was sunk into a 60 feet deep shaft beneath the bridge itself. When the bridge needs to turn, the water is released under pressure thus providing the hydraulic power needed to actuate the motor. It can turn through 180°in only 3 minutes – turning 900 tons and a 281 foot span!

Modern Times

The work began in 1868 and the bridge was opened until 1876. It made its first turn for shipping purposes on July 17, 1876. It would be about 80 years before a major design change was made: replacing the steam-powered pumps with electric pumps.

The swing bridge remains in working order, so many years later, and still uses the original hydraulic motors designed and installed by Lord Armstrong. It isn’t required to swing as much as in its heyday, but the Swing Bridge over the River Tyne is still fully functional and remains the largest bridge of its type in the world.