3 Things Your Competitors Can Teach You About Final Drives

Jan 10th 2020

Final drives keep your critical equipment running, and when that equipment fails, you lose money, time, and possibly even contracts. Here are 3 things your competitors already know about final drives and how to keep them going!

1. Maintenance is key.

In the Final Drive Parts blog, we focus on maintenance quite a bit -- even though you might say it’s bad for our business. We know that the most important thing you can do to keep the final drives in your equipment running reliably and efficiently is to maintain them and follow-up with repairs in a timely manner. That means things like changing out the gear oil on a regular basis, checking for possible leaks, and replacing the case drain filter when needed.

We recommend that you go back through your manufacturer’s recommendations and make sure that your maintenance plan adheres to them -- like your competition already does. Those maintenance plans weren’t drawn up at random – they were developed to make sure the equipment lasted at least through the manufacturer’s warranty period.

2. Don’t ignore those leaks.

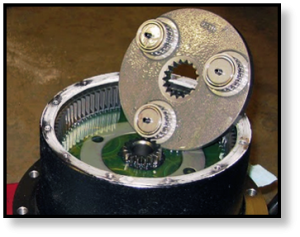

A minor leak behind the sprocket may not seem like a big deal, but it can escalate into catastrophic damage very quickly. When seals begin to fail, they begin by letting hydraulic fluid (or gear oil, depending on where the leak is) escape. With time, this will compromise the efficiency and performance of your final drive. However, when a seal is letting fluid escape it also starts to let contaminants in, like the final drive taken off a Bobcat 331 shown above. These can seriously damage your final drive and your hydraulic system. Left alone, leaking seals will lead to catastrophic damage. Attend to those final drive leaks as soon as possible -- just like your competition takes the time to do.

3. A reman final drive is an economical option.

Sometimes a final drive has simply outlived it useful life and you need to find a replacement. You can pay and arm and leg to the dealer for a brand-new replacement, purchase a used final drive that may not last long enough to be worth what you paid for it, or you could purchase a re-manufactured final drive.

Depending on where you purchase it and what kind of final drive it is, you can save 40% or more over the cost of a new drive. Some companies offer warranties for the re-manufactured final drive, and depending on the level of quality you can get a drive that not only meets but exceeds the OEM specifications. Your competition is already doing this ... don't you think you should, too?

Conclusion

To stay competitive, your equipment needs to be ready to move. By maintaining your final drive and addressing leaks you can keep quite a few problems at bay. When your final drive has worn out, keep in mind that re-manufactured final drives are an excellent option in terms of both cost and quality. These three simple rules can help you outpace the competition.