The Worst 3 Track Drive Mistakes Equipment Owners Make

Nov 4th 2018

If you own a CTL (Compact Track Loader) or MTL (Multi-Terrain Loader), you know that your machine needs a functioning track drive motor in order to move. These hydraulic motors are a vital part of your equipment, whether it’s an ASV compact track loader or a CAT multi-terrain loader — and they are also a commonly neglected aspect of compact equipment. In this Shop Talk Blog post, we are going to talk about the three worst mistakes equipment owners make when it comes to their track drives. Do you know what they are?

Worst Track Drive Mistake #1: Not Changing the Gear Oil

The planetary side of your track drive uses a reducing gear system to convert speed into the torque needed to make a CTL move. That part of your track drive needs gear oil to function properly. If the gear oil runs low, it will lead to severe damage to the components in the gear hub, including gears and bearings. When these components suffer damage, they repairs and replacement parts can become expensive very quickly. If your gear oil looks like sludge, it is way overdue for a change.

When the gear oil isn’t changed regularly, key lubricating properties can degrade and it won’t work as effectively. If the gear oil is no longer doing its job of lubricating, reducing friction, and conducting heat away from key components, your final drive will not be as efficient and will begin to suffer damage. A simple thing like neglecting the gear oil can lead to costly repairs — compact track loader parts are never cheap.

Worst Track Drive Mistake #2: Neglecting Leaks

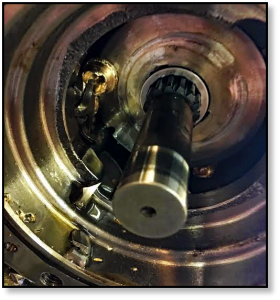

Another common but serious mistake involves neglecting leaks. A failed, leaking seal not only allows key lubricants and hydraulic fluid to leak out, but can allow abrasive contaminants into your track drive. Many of the key components in your track drive can be destroyed by abrasive damage or metal-on-metal contact. The longer it is allowed to go on, the worse the damage will be. The image below shows a contaminant-filled sludge in a failed final drive that was sent in for repair. The resulting damage was extensive.

As soon as leaks are spotted, they need to be addressed as soon as possible. One way to detect leaks related to gear oil is to check your gear oil level on a regular basis. I f your gear oil consistently runs low then there is leaking seal that needs to be attended to immediately. You may also notice a leak coming from behind the sprocket — that is usually gear oil. If there are large amounts of fluid present or the fluid is of a thinner consistency, the leak is hydraulic.

Worst Track Drive Mistake #3: Not Checking the Case Drain Filter

You may have noticed that we dwell quite a bit on case drain filter problems*. Case drain filters are the number one cause of catastrophic final drive failures. Here’s what happens:

- Case drain filter becomes clogged

- Hydraulic fluid increases in pressure because it’s flow through the case drain line is hindered

- Hydraulic fluid seeks an escape path with minimal least resistance

- That path is the oil seal between the planetary hub and the hydraulic hub

- Oil seal is blown, and hydraulic fluid accesses the gear hub

- Once in the gear hub, the pressure continues to build

Depending on how long the problem goes unresolved, bearings can be damaged, the rotary group can be destroyed, and the track drive cover plate can be completely blown off. The damage cannot be repaired, and the final drive is totaled.

Preventative Maintenance Is Vital

If you want your track drive running efficiently and reliably, then remember these three things: change the gear oil, don’t ignore leaks, and check the case drain filters. These often overlooked steps in preventative maintenance can save you thousands of dollars in repairs. Don’t throw your money away on needless repairs — take care of your track drive motors.

*Note: not all systems have case drain filters.

Check out our latest reman final drive hydraulic motor inventory for ASV Compact Track Loaders or look up your manufacturer brand final drive.