Lapping and Final Drives: Three Questions You Probably Never Thought to Ask!

Dec 30th 2018

Restoring Final Drives Using Lapping Tables

One of the tools we use at Final Drive Parts to restore certain types of damaged final drive components to usability is a lapping table. Lapping is a process used to produce a smooth, flat surface on a part. The particular process we use for final drive parts is officially termed free abrasive lapping.

What is a Lapping Table?

Basically, a lapping table is a big, rotating stone that you lay a part on, with the part surface that needs to be smoothed laying face down on the stone. An abrasive mixture called a slurry flows at regular intervals onto the part and the stone. The slurry is what produces that flat surface: as the stone rotates, the slurry grinds metal off the part until it’s surface is flat. The slurry we use is actually oil mixed with a cutting compound.

How Is It Used?

A lapping table can be used to restore surfaces that need to be smooth. It can bring certain types of components back to OEM specification to minimize case drain. These kinds of components need to match and mate perfectly; otherwise, the unit will suffer blow by and won’t have as much power. In fact, when a motor is being evaluated this is a common procedure used to restore power to the unit.

Another direct use of lapping is to restore damaged surfaces. Below you can see part of the rotating group out of a Bobcat T190 final drive. It has dents, divots, and scratches on the part of the surface that needs to be as flat and smooth as possible. The markings that you see on it were made by a technician evaluating its condition, identifying where the problem areas are located.

Another direct use of lapping is to restore damaged surfaces. Below you can see part of the rotating group out of a Bobcat T190 final drive. It has dents, divots, and scratches on the part of the surface that needs to be as flat and smooth as possible. The markings that you see on it were made by a technician evaluating its condition, identifying where the problem areas are located.

Depending on how bad the damage is, this part can be re-smoothed using the lapping table. This process is much more economical that simply replacing the part. So the lapping table would be used to create a new, flat surface that is free of the dents, divots, and scratches. In this case, that process proved successful. However, lapping won’t always make a part with a damaged surface usable again.

How Does the Lapping Process Work?

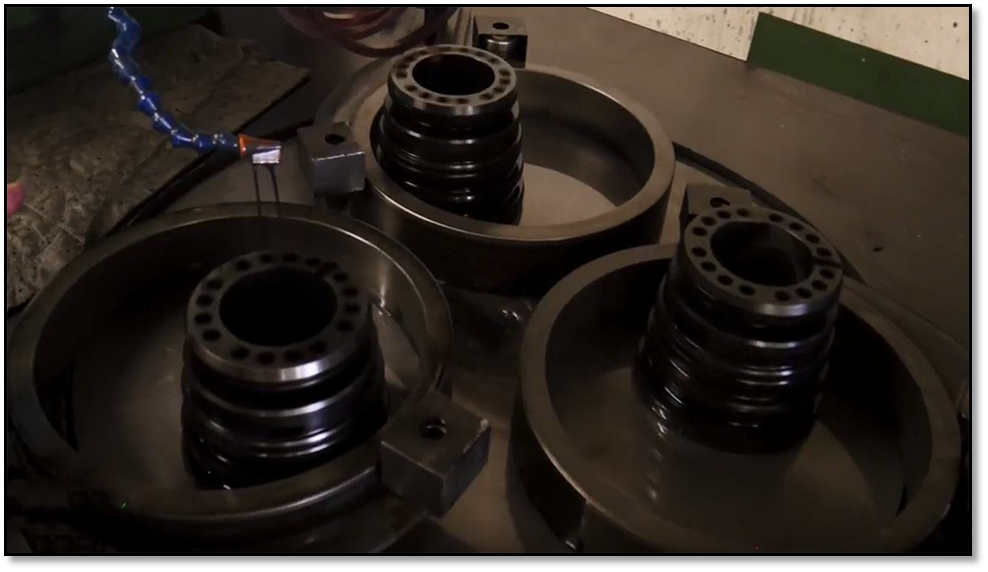

The image below shows the lapping table at work. The blue flexible tubing with the orange tip is what is used to automatically distribute the slurry onto the rotating stone. In this case, the stone has three rings on it to allow three different parts to be processed at the same time. Parts usually take on average 23 minutes with the settings we have on our machine. Some parts, of course, may take longer.

Even after lapping, the parts are re-evaluated to determine if the lapping process did make them serviceable again. If it does not restore the surface sufficiently, the part is discarded.

Are There Parts Too Damaged for Lapping?

Here we see a distributor out of a Bobcat T300 final drive. You can see the grooves and scratches present on the surface. It’s covered with divots, dents, and chips to the point that it is not salvageable, even with the lapping process. This most likely occurred as a result of damage inside the final drive while it was running that sent metal particles and debris throughout the system. This is a good reason not to keep running equipment when it is malfunctioning or damaged.

Conclusion: Lapping Process and OEM Specs

The lapping process can be used to repair damaged surfaces, restore certain types mating parts to OEM specifications, and help restore motor power. The process itself involves a lapping table consisting of a large, flat, rotating stone and an abrasive slurry that grinds metal away to leave behind a flat, damage-free surface.