Final Drives: Keeping Your Bearings

Feb 24th 2019

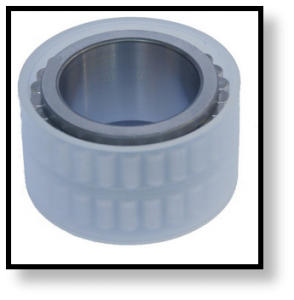

Bearings in Final Drives

Bearings serve a variety of purposes in a final drive, such as maintaining the alignment and position of shafts and gears. They also minimize friction, which in turn reduces the amount of heat generated. Because of how effective they are at reducing friction, bearings effectively reduce the wear and tear of other key components . Bearings are a critical part of any mechanical system, and final drives are no exception.

Useful Life of Bearings

Bearings have a limited life and require proper care and maintenance to achieve it. One of the causes of premature bearing failure is contaminated lubricant. We know that lubricant provides a low-friction, protective film between interacting surfaces in a final drive. When the lubricant (whether its hydraulic fluid or gear oil) becomes contaminated, it will result in damage to the surfaces of the bearings. This reduces their effectiveness and compromises their useful life.

Final Drives and Bearing Failures

When a bearing fails, it will begin to take other components with it in a domino-like effect. The picture below shows the extensive damage done to a Bobcat T180/T190 final drive when one of the main bearings went out. The metal looks like it’s been chewed up, and is most definitely beyond repair. This particular final drive will need to be replaced.

Preventing Bearing Failure in Your Final Drive

There are certain things that you can do to prevent bearing failure. The first is to make sure the final drive has enough gear oil — some of bearings in the final drive are contained in the planetary side, such as the gear bearings. The gear oil lubricates not just the gears but the bearings, too. It’s not that difficult

It’s not that difficult to check the gear oil and top it off as needed. You should be careful to follow manufacturer guidelines on how often to check and change out the gear oil, as well how what type of gear oil should be used with your final drive.

Keep in mind, though, that if you have to keep topping off the gear oil it could indicate a leak that needs to be addressed. Always take leaks very seriously! Failing to do so can result in expensive, catastrophic damage over time.

Another way to help prevent bearing failure is to make sure that you never mix different brands or grades of grease, lube, or oil. Not all lubricants are compatible with each other, and mixing them can end up defeating the whole purpose of a bearing. When you do add a new type of lubricant, make sure you have plenty of time to drain as much as possible of the original lubricant out of the system

Another way to extend the life of your bearings is to not abuse your equipment. That means running it at high speeds when not necessary, not subjecting it to loads or forces that it wasn’t designed for, and just using common sense.

Conclusion: Final Drive Bearings are Critical

Bearings are a critical part of any mechanical system, including your final drive. To help extend the life of your bearings, and of your final drive as a whole, make sure to check and change the gear oil regularly, avoid mixing different brands and grades of gear oil, take any kind of leaks very seriously, and don’t abuse your equipment.