Final Drive Cores and the Remanufacturing Revolution [VIDEO]

Posted by Dr. Sara McCaslin on Jan 15th 2024

These seemingly unassuming components, often relegated to dusty corners and forgotten yards, hold the key to a sustainable and cost-effective solution for extending the life of your machinery.

At Final Drive Parts, we're not just experts in replacing worn-out parts but ardent advocates for the potential within every final drive core. At their core (pun intended), these units represent a remarkable opportunity to bridge the gap between environmental responsibility and fiscal prudence. But final drive cores may seem confusing, so let's shed some light on them.

What is a Final Drive Core?

The word "core" refers to the external housing of a final drive. As long as the housing, ports, and flange are in good condition, a used core can be salvaged for the basis of a remanufactured drive. And that makes it valuable to us and you.

What is an Acceptable Core?

The core must meet certain conditions to be valuable. For instance, it must be free of cracks or indications of mechanical failure, the threads must be intact, and the flanges can’t be bent. In many cases, the parts within the core can be reused after cleaning, inspection, and reconditioning (except for seals, gaskets, and bearings). However, exterior rust and encrusted debris are not the same as damage. Rust and debris can be cleaned and removed. Core damage refers to issues such as broken threads, cracks in the housing, and missing cover plates.

What Makes a Final Drive Core Valuable?

What makes a final drive core valuable? One factor is how easy it is to find a replacement drive. If replacements are easy to find, there will likely be little demand for that core. This is because newer model machines, drive motors still under manufacturer warranty, and equipment still supported by the OEM all have readily available replacements. Hydraulic shops that perform final drive repair and rebuilds are not interested in these cores because they take up a lot of space for such low demand.

The condition of the final drive core is also a factor in determining its value. A core in good condition will be worth more than one damaged. However, even a core that has been gutted, as long as the exterior is in good condition, could be used for a reman final drive.

Final Drive Parts and Cores

Some final drive cores are usually in high demand. Here at Texas Final Drive, we are generally looking for Bobcat T-Series final drives, including Bobcat T140, T180, T190, T200, T250, T300, T320, T550, T630, T750, and T770 models. We're also interested in Kubota SVL 75-90, CAT 320, 330, 336, and John Deere.

Sometimes, there is also a demand for Bobcat 331 or 334 and other brands and models. But even when there is a high demand, some final drive shops may not be interested. They may need more space for it if they already have several unused cores on hand.

Final Drive Core Buyback Programs

Some final drive motor vendors have core exchange programs. In these programs, you send in your old final drive of the same make and model as the replacement you're purchasing. A core exchange may be required when you buy a reman/rebuilt final drive. You may see a "core charge" tacked onto your invoice at Final Drive Parts. If it is usable, that charge is fully refundable upon the company's receipt of your old core. If you don't have a core, you must pay the core charge.

Core buyback programs allow you to sell us a core without purchasing a reman final drive. This saves you the trouble of setting up an eBay seller account or something similar, and the purchasing company usually covers shipping.

Wanting to sell a core? Fill out the information on this page: Core Buyback Program.

Final Drive Core Charge Policies

Here’s our Core Charge Policy:

- A core charge is assessed on certain products and parts sold by WFP. The core charge will only be refunded upon meeting the following conditions:

- The core part must match exactly the manufacturer, part number, and model of the part sold to the customer.

- The core must be complete and assembled, including all parts.

- The core must be returned within 30 days of the original order shipment.

- Core must not show signs of negligence, abuse, or damage, including but not limited to damage or loss of parts during shipping.

Examples of core negligence, abuse, or damage include rusted internal components, water damage due to improper or extended storage times, damage during shipping, improperly packaged components, and parts from multiple different cores shipped together to look like one core. WFP reserves the right to adjust the core return credit for any of the above and other reasons at its full and sole discretion. The customer must send in their core part for inspection if they have concerns about whether their core will receive full credit.

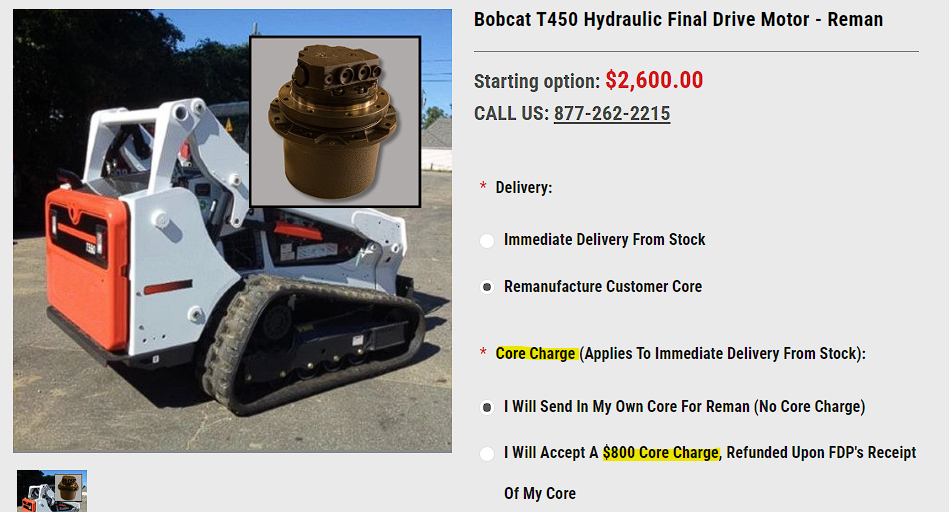

Example

Let's look at an example. We discussed the demand for reman final drives for model Bobcat T-series machines, and you’ll probably see a core charge for one of these. For this Bobcat T450, the core charge is $800For larger final drives that can be remanufactured, core charges can be up to $5,000 or even more. If these numbers seem high, keep in mind that you get the core charge refunded once your core is received and meets the core charge policy conditions.

Shipping a Final Drive Core

Here’s a video we made on how to shop a final drive core:

And here are some key things to remember about shipping it:

- Remove the sprocket (if it is still attached)

- Do not disassemble it

- Secure loose parts in a heavy-duty plastic bag

- Thoroughly seal all the ports so nothing leaks out during transit

- Don't use a wooden crate -- they don't get handled well during shipping

Remanufacturing: Saving Money, Saving the Planet

The remanufacturing process transforms these cores into virtually new final drives. By utilizing salvaged parts and meticulously rebuilding them to OEM specifications, Final Drive Parts offers a compelling alternative to brand-new units. This translates to significant cost savings for equipment owners, putting more money back into their operations.

But the benefits extend far beyond the balance sheet. Remanufacturing breathes new life into existing materials, drastically reducing the need for new resources and minimizing the environmental impact of manufacturing new final drives. It's a win-win scenario for both your wallet and the planet.

By understanding the power of final drive cores, we can contribute to cost-effective equipment maintenance and embrace a more sustainable future for the heavy equipment industry. Every core we reclaim represents a victory for your bottom line and the environment.

![Final Drive Cores and the Remanufacturing Revolution [VIDEO]](https://cdn11.bigcommerce.com/s-lbnln0ppxx/images/stencil/original/uploaded_images/final-drive-cores-and-the-remanufacturing-revolution.png?t=1705357426)