Bobcat 331 Mini-Excavator: Rotator Group

Sep 10th 2018

Bobcat 331 Final Drive Rotator Group

The rotator group in a final drive is one of the most important — and most expensive — assemblies. In this article, we are going to look at the parts of the rotator group in a Bobcat 331 and discuss the type of damage they typically experience. Then we’ll talk about how to prevent that same kind of damage.

Major Parts of the Rotator Group Assembly

The piston block holds and guides all nine piston cylinders. In the image to the left you can see that installed are three ball guide pins for holding the ball guide in place. If a piston seizes in one of the bores in the piston block, the piston shoe can be pulled off. Severe damage to the piston block takes the form of cracks between the bores.

There are nine pistons in the rotator group for the Bobcat 331. Hydraulic fluid enters under high pressure at the base of the piston cylinder and exits the tiny hole that is visible on the piston shoe. The piston shoes should have a smooth, reflective surface (like the one shown), and not be scarred or scratched. The barrel of the piston should also have a smooth surface finish with no scratches.There should be limited play between the shoe and the piston itself. If you can “pop” the shoe, there is a problem.

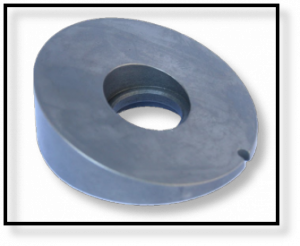

The piston shoes interact with the swash plate, shown above for the Bobcat 331. Damage to the swash plate causes a scratchy appearance with uneven wear. You may also see grooves that have formed on the surface. These will adversely affect its performance.

The retaining plate holds the piston shoes in place. If the piston shoes become loosened from the piston cylinder, you may see some unusual signs of wear here.

Above you can see the lower drive shaft from the Bobcat 331 rotator group. If this is broken, it is possible to identify the mechanism behind the failure. A cone-shaped break indicates torsional fatigue, while a straight break indicates bending.

This is the valve plate, which lays against the base of the piston block. A damaged valve plate will show signs of scarring and scratching with a smeared running surface.

How to Damage the Final Drive Rotator Group

If the hydraulic fluid isn’t analyzed and changed according to schedule, contaminants build up and will damage these parts in the rotator group. They can scratch, scar, groove, wear, break, and erode, compromising performance and eventually leading to catastrophic failure of the final drive. To make things worse, you won’t usually know that your rotator group is severely damaged until it has failed.

How to Prevent Damage to the Final Drive Rotator Group

There are two keys to preventing the kind of damage described: the first is to change out the hydraulic oil as recommended by your machine’s maintenance schedule, and the second is to regularly check the case drain filter, cleaning it or replacing it as necessary.